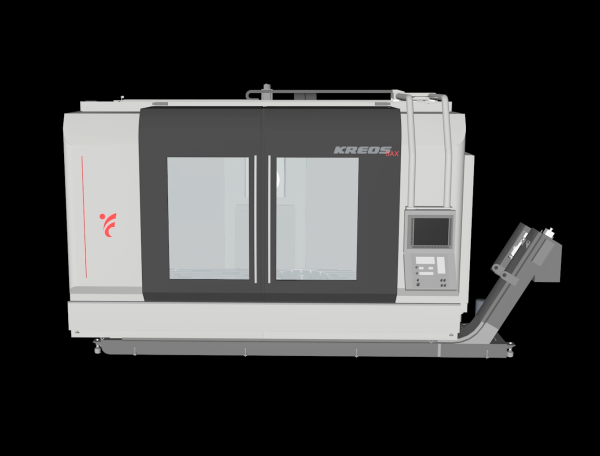

Kreos 240-400

/ 3⇢4⇢5 axis machining centers

KREOS machining center was born from the wide experience gained by FAGIMA in designing and construction of machining centers with moving column. It was studied to meet every potential Costumer’s expectations: even with reduced sizes, KREOS ensures a high stiffness and structures’ strength, which blend perfectly with agility and speed in machining executions.

The KREOS therefore faces the market segment where the greatest demand for 5-axis moving column machines is addressed. FAGIMA offers, in the standard version, 2 different alternatives on the X axis (2700 and 4000 mm) while 830 mm determine the stroke in Y and 850 mm the stroke in Z.

Characteristic of KREOS is the elegant design, but also some innovations in components. Moreover designers developed the project with aim to reduce as much as possible the overall dimensions of the new machine.

KREOS structure is a monolithic base with high loading capacity, without any complex foundations requirement. The column holder-carriage slides on it, through roller guideways (feature in common for all 3 axis X, Y and Z). Inside the column, two groups are located: the tool changer and the exchange arm.

The usual and timely attention was obviously reserved for the components, predominantly of Italian origin, a feature that respects a well known charactetistics of FAGIMA products. The standard version is susceptible to different combinations and guarantees the largest customization of the machine according to the particular needs of each Customer, up to the extra-strokes on the X axis.

Things to know

Main structures of Kreos are made thanks to a new tecnique, alternative to traditional welded steel, cast iron and granite elements. It starts from making an external shell, that can be entirely or partially filled. The exploited conglomerate has a mix design of elements, specifically worked out to optimise the mechanical characteristics requested by the world of machine tools and machines in general. Several advantages come from this technique, especially for middle dimensions machines like Kreos:

◼︎High dynamical stability of the machine

◼︎Non-deformability over time

◼︎Minor vibration in the tool contact area

◼︎Minor thermal generation in the tool/piece area